Vibrations and process variables in a system with vibro

The additional function Vibro supplements the existing ProfiSignal functions with special vibration measurement diagrams such as FFT, cascade, time signal, bode, envelope curve as well as orbit and spectrogram.

With the additional Vibro function and the Vibration measurement Expert Vibro you have a system that can record not only standard process parameters such as pressures, currents, voltages, temperatures etc. but also vibrations from bearings and shafts.

However, not only online values, but also historical data can be called up and analysed at any time. To do this, simply call up the time range in the current visualisation.

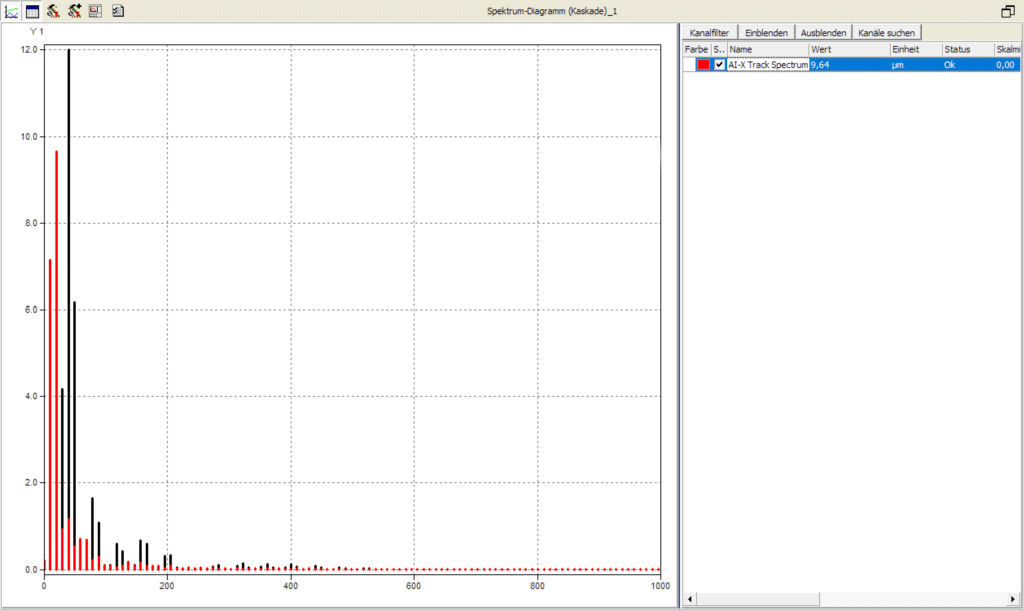

Reference spectrum in the spectrum diagram

A reference spectrum can be displayed in the spectrum diagram in addition to the current measurement data. This allows you to easily track the development of a vibration spectrum over time and gain valuable information, for example about the wear of a machine or system.

Product highlights from Vibro

- Extension of the ProfiSignal software with the special vibration measurement diagrams time signal, orbit, shaft centreline, polar, FFT, envelope curve, cascade, order analysis, spectrogram and Bode

- On-/offline display, evaluation of the values measured with the vibration device Expert Vibro

- Acquisition, visualisation and analysis of process measurement values and vibration measurement values in one system

- Documentation of the vibration values by means of report generator, whereby all special diagrams are also available

Shaft vibration diagnosis and monitoring

Shaft vibration is primarily about recording and monitoring the static and dynamic motion of a rotating shaft, such as on hydropower turbines, compressors, etc.

Bearing vibration monitoring

In the case of bearing vibration, on the other hand, the absolute bearing vibration of rotating parts mounted on roller bearings is to be recorded and evaluated, e.g. in electric motors, pumps, rollers, etc.